Gold concentrations are spotty, even in known gold-bearing areas, so most prospectors sample and test often using a simple gold pan.  They keep moving until they get good results. Once you find a spot with fairly large amounts of gravel that yields good gold, then it’s time to bring in a sluice box. A sluice is simple to operate and has been used all across the world for thousands of years. A sluice is often the first large-scale concentration device purchased by miners. The advantages include low cost, versatility over a wide range of material and water conditions, and ease of setup and use.

They keep moving until they get good results. Once you find a spot with fairly large amounts of gravel that yields good gold, then it’s time to bring in a sluice box. A sluice is simple to operate and has been used all across the world for thousands of years. A sluice is often the first large-scale concentration device purchased by miners. The advantages include low cost, versatility over a wide range of material and water conditions, and ease of setup and use.

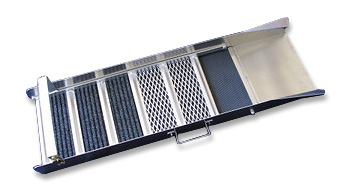

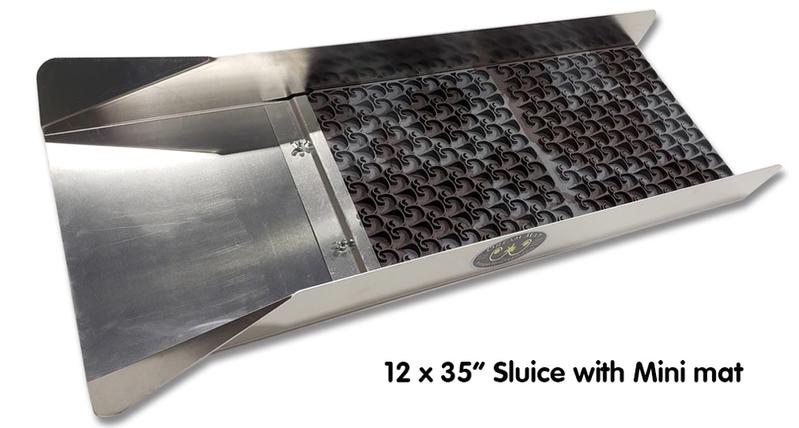

There are many different types of gold sluices and brands from which to choose. Sluices come in a variety of sizes, most with gold-catching matting, carpeting or miner’s moss in the bottom that you need to clean up at the end of the day. Other models contain no matting or carpets but can still catch fine gold. Whichever sluice box you use, sluicing techniques are overall fairly straightforward and it’s open design allows you to see how the material is being processed and recovered. As you get started sluicing, or begin to improve your technique and results, you can maximize your gold recovery by keeping in mind proper selection and setup, material classification and processing. Learn how material and water speed affect gold capture, and how fine-tuning your techniques to match material type and water conditions can lead to increased recovery.

Proper Setup of your sluice is by far the most important aspect of gold separation and recovery. Some common mistakes too watch out for are:

- Improper sluice angle is probably the most common error that gold miners make. The old rule of thumb is to set sluice angle to one inch per foot, but that usually results in too much water velocity, resulting in improper breakdown and separation of heavy concentrates and material moving through the box too quickly. Instead, focus on water velocity, not so much of the angle. Measure 12 inches down your sluice box and make a mark prior to going out to a stream. Feed your material into the sluice in a side-to-side motion. As the material moves through the box, count a slow “one thousand one” and your material should be passing your mark. Only if it needs to be faster should you increase your rear angle. If it needs to be slower, decrease it. This is solely dependent on your classification. If you change classification, you might need to change the angle of your box.

- Too much water in the sluice is a common error. Having too high of a water column allows fine gold to run above the capture area. Running too much water also allows the material column to be wider and denser, which can carry gold out of the box without it being pushed into the capture area.

- Horizontal leveling of your sluice is critical to proper movement of material, as well as the separation and capture of fine gold. As the material travels down the slick plate and moves down the sluice, it is very important to utilize the entire capture area to process the material. Improper horizontal leveling forces material to one side or the other, leaving one side clogged while the other side is not processing at all.

Matching material classification and processing speed/volume of material to your sluice is critical to maximize gold recovery. First pan test the material you run through the sluice to provide you with both the size and quantity of gold in the material. In order to capture small gold in quantity, finer classification is usually necessary. While it takes more time, miners get the benefit of removing more material that is not gold bearing - making each bucket both more valuable and easier to run through the sluice box. Processing speed and volume of material to put in sluice (by hand or by scoop) must be matched to the volume and velocity of the water. If too much material is introduced into the flow, the water velocity will slow down and cause the sluice to back up and lose gold. It is much better to gradually add smaller amounts of material to the flow. If you are adding material into the sluice using a scoop, avoid adding material like an ice cream scoop because that disrupts the water flow. Instead, turn the scoop into the flow and gently move the scoop side-to-side while the water pulls material.

Matching material classification and processing speed/volume of material to your sluice is critical to maximize gold recovery. First pan test the material you run through the sluice to provide you with both the size and quantity of gold in the material. In order to capture small gold in quantity, finer classification is usually necessary. While it takes more time, miners get the benefit of removing more material that is not gold bearing - making each bucket both more valuable and easier to run through the sluice box. Processing speed and volume of material to put in sluice (by hand or by scoop) must be matched to the volume and velocity of the water. If too much material is introduced into the flow, the water velocity will slow down and cause the sluice to back up and lose gold. It is much better to gradually add smaller amounts of material to the flow. If you are adding material into the sluice using a scoop, avoid adding material like an ice cream scoop because that disrupts the water flow. Instead, turn the scoop into the flow and gently move the scoop side-to-side while the water pulls material.

When setting up your sluice, you are bound by the conditions at hand. However, three factors are in your control: water input, water height and speed (sluice angle), and introduction of material into the sluice. One or more of these factors may need to be adjusted as conditions change. It all comes down to which of the two types of water you will be forced to use. When using stream flows, you are bound by the characteristics of nature— water speed, depth, ability to change sluice angle. Miners must harness the natural conditions. Sluice stands can sometimes help. Mechanical flow provides miners with the ability to regulate all facets of material processing. You can control flow and depth at the flare, and sluice angle (water speed) at the rear of the sluice. These changes are dictated by the material you are processing.

Understand your sluice’s capacity— how much can the sluice hold before it loses its ability to separate heavy materials and capture gold. If you begin to see material slippage (movement of heavy material down the sluice) or movement of captured gold, it is time to remove your sluice from the stream, then clean and reset it. If you consistently process difficult material or your collection method has a low capacity, then setting up a cleaning schedule will save you from losing gold.

There is no one perfect sluice configuration that fits all water conditions and material types. Therefore, it is always best to match sluice configuration to the conditions and material at hand. As you run material, continually monitor how the sluice is processing the material (liquefaction, separation, capture and expulsion of waste materials). These basic techniques can be used with a variety of sluice designs, allowing miners the ability to recover gold as conditions change throughout the year. Also know that the real secret of successful prospecting is not only in operating the equipment, but in the skill of finding those natural gold catches. Learning to read the river or stream and recognize the places where gold might accumulate and then sampling those places to see if you are correct is the best technique. Inside bends, behind boulders or bedrock outcrops, and inches above the stream flow are all good places that you might sample, but there are plenty of other possibilities as well. The low-cost advantage of sluicing allows you to tailor equipment to conditions and material in your area. Good luck!

configuration to the conditions and material at hand. As you run material, continually monitor how the sluice is processing the material (liquefaction, separation, capture and expulsion of waste materials). These basic techniques can be used with a variety of sluice designs, allowing miners the ability to recover gold as conditions change throughout the year. Also know that the real secret of successful prospecting is not only in operating the equipment, but in the skill of finding those natural gold catches. Learning to read the river or stream and recognize the places where gold might accumulate and then sampling those places to see if you are correct is the best technique. Inside bends, behind boulders or bedrock outcrops, and inches above the stream flow are all good places that you might sample, but there are plenty of other possibilities as well. The low-cost advantage of sluicing allows you to tailor equipment to conditions and material in your area. Good luck!