Monday, July 25 2016

The following is an excerpt from the extensive and informative "Going Cubular" article that appears in the Whether you're prospecting in a stream or desert, mine alone or run a large operation, chances are you've seen or personally operated a Gold Cube. This super concentrator is everywhere! Mike Pung, the co-inventor, demonstrates this workhorse at all the GPAA Gold & Treasure Shows, and it's been made famous on the GPAA-produced Gold Trails and on the Discovery Channel's Gold Rush and Bering Sea Gold reality TV shows. The celebrities all use it, including Dakota Fred, Parker Schnabel, Todd Hoffman, Vernon Adkison, and Emily Riedel. Save Time with the Gold Cube Why do so many famous gold miners, as well as average guys and gals, use the Gold Cube? Because it saves time. Lots and lots of time! "What would normally take about 8 hours of cleanup with a gold pan is reduced down to about an hour with the Gold Cube," explains Mike Pung. "Anybody with a lot of concentrates or who has a dredge or if you're running a big operation views the Gold Cube as more of a clean up tool. But to many recreational prospectors and small-scale miners, the Gold Cube is their primary piece of equipment in the field. The Gold Cube can process the black sands and hold the fine gold like no other machine, hence the slogan Cube It or Lose It!" Fine gold is defined as anything that is 20 mesh and smaller (mesh refers to the number of holes per linear inch in a screen or classifier). "Once you start getting down below 20 mesh, if you're not using a Gold Cube, you are blowing out most of the fine gold. You are keeping the big stuff, but are losing a lot of fine gold. If it's 50 mesh and minus and you are using a sluicebox, you're losing most of that gold if you're running continuously all day," says Mike. How the Gold Cube was Invented Mike Pung was bitten by the gold bug in 2006 and met co-inventor Steve "Red" Wilcox shortly after his first trip to the Klondike. Besides sharing a passion for prospecting, the two men shared a common enemy: black The Gold Cube is designed to handle up to 1,000 pounds of material an hour. "It can take a thousand pounds of dirt per hour and reduce that material down to a cup and a half of concentrates," said Pung. "If you put a cup and a half in there, you are going to end up with a cup and a half. But if you shovel a half ton of dirt into it, you will still end up with a cup and a half. The longer you run it, the more it's going to concentrate. It's not the number of buckets you have to monitor. It's the weight of the material. For example, 1,000 pounds of regular gravel amounts to about 16 to 18 buckets, whereas the black sands along Lake Superior are much heavier, so 1,000 pounds of material may fit in only 4 or 5 buckets." How the Gold Cube Works Imagine a fine gold particle, 19.3 times heavier than the moving water that suspends it. The trick is to use the water to separate the lighter material from the heavier, through stratification or layering. "The low pressure zone behind a riffle is called an eddy which rolls horizontally, and the vortex churns vertically like a tornado," explains Mike. "What happens is the vortex churns the material, separates the lights from the heavies, and the gold sinks to the btoom. And when it sinks, it stays there until something heavier wants to displace it. As gold sinks to the bottom of a vortex pocket that's already full, it will displace something equal to its size. The Gold Cube and the vortex technology basically operates on a replacement system, so when you've got something heavy it sinks and something else has to get kicked out, so heavier just keeps replacing lighter material. The longer you run it, the heavier that pocket is going to get. And once it is completely full, it's going to have to find another pocket because that pocket is full of gold. Which is not a bad problem to have!" Is a 3 Stack or 4 Stack Best?

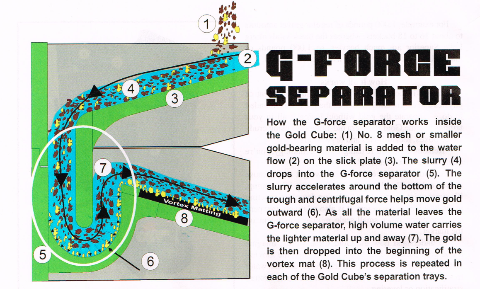

The rounder the gold, the faster it's going to sink. If you have fine three dimensional gold you're probably never going to see any gold past the first 2 or 3 inches of the very first try unless you've completely loaded it up with gold. It's going to find some place to sit... that's called hydrodynamics. Mike Pung explains further, "If you've got three dimensional gold closer to the source, you know that all you're going to need is a three-stack Gold Cube because the first tray is going to catch most of the gold." G Force Separator In the G-force separator where the Gold Cube trays drop down and around, the water whips around the bend. Get Rid of Those Bubbles! Setting up your Gold Cube for the first time is not too difficult; some say the hardest part about setup is putting together the stand. It will take 10 or 15 minutes and most of that time is spent getting the mats very wet. You must make sure the mats are wet all the way down to the bottom of the vortex pocket so they don't hold a bubble. If they hold a bubble, gold can ride right over the top of it. Getting rid of the bubbles is very important! If your mat is wet and it looks like there are a bunch of diamonds shining in the sunlight in there, those are really bubbles and that's not where the gold is going to sit. There are 7,000 vortex pockets on that mat. To get rid of the tiny air pockets, put your thumb over the end of a hose to create water pressure to force the water in deep while spraying the mats. When your mat looks black and not shiny with bubbles, you will get good gold retention. There are two main accessories available for use with either the three stack or four stack units. Gold Banker: The Gold Banker is placed over the Gold Cube and serves as a built-in classifier with spray bar, which eliminates the need to classify material before running it. It's available in Stainless (recommended for salt water) or an Anodized punch plate. If you're a rockhound, you'll want a Gold Banker. "You've never had a better way to look at rocks because they're clean and wet. I've found arrowheads, petrified wood, gems, and all kinds of stuff in the Gold Banker," says Mike. Trommel: The trommel allows you to shovel unclassified dirt and rock directly into the hopper. The trommel (16 inch long barrel x 5 inch diameter, classifying to 3/16 inch) then trumbles and washes the material before it enters the Gold Cube trays. Ready to "Go Cubular?!" Click here for more information, to watch videos, and to order the Gold Cube and/or accessories. Saturday, July 02 2016

Although there are many variables that go into catching gold in a sluice, perhaps properly “tuning” your sluice is the most critical. A few months ago, Steven “Doc” Vetter, owner of Gold Hog brand mats, wrote an interesting article for Gold Prospector Magazine that focused on a few key factors that all miners should pay attention to. The following ideas from his article are all about achieving the proper tuning exchange, meaning letting the junk flow out, or be worked out by exchange zones, and holding the stuff you do want—gold. A well-tuned sluice will have heavy gold concentrations up top, medium gold in the middle, and trace gold near the end Hydraulic Equivalence: By definition, “hydraulically equivalent” (HE) refers to particles of varying size, shape and density that fall out of a water flow and deposit in the same area. While quartz rock and gold vary greatly in specific density, you can make them collect in the same place by making the quartz rock bigger and rounder. A 2 inch quartz rock and a 1 mm sphere of gold will fall through water and deposit in about the same place— making them hydraulically equivalent (HE). An opposite example is a .25 inch round piece of gold and a .25 inch round piece of quartz. The gold will sink through the water and likely land straight down. The quartz rock, however, will not fall as fast and will be pushed several feet away before it settles. These two items are not HE. The shape of the gold has a big influence on its HE. Flat things move more easily than spheres when either moving water or air is introduced. HE is a huge factor in gold mining and is often the main reason for classifying material to a certain size— the theory being if everything is about the same size, the heaviest material will stay in the sluice. When you slow down a sluice, you start to have a traffic jam. Things that are HE all want to gather in the same deposit zone and you start to gather/open the window for more non-gold particles to pile up and that’s not good. Incremental Processing: A great analogy of how this principle works is to picture a city bus. Imagine a rule where all passengers must enter through the front and must exit through the back. As they enter, passengers must fill the seats in the front of the bus first. Every time the bus makes a stop (you shoveling dirt into the hopper of your highbanker or sluice), the first few rows fill up quickly and remain full for a short period of time. As a new passenger (each new shovel full of material) gets on and finds the front seats taken, he must move further down the bus (sluice). The result is a bunch of folks all competing for the same seats up front and when there are no seats up front, they must take the next available one. If all the seats get full, a passenger (your paydirt) never even gets to sit down and exits the bus (sluice) without ever sitting (collecting in the riffles). As the working zones in your sluice fill up, slurry material will move down to the next zone before it settles there. During times of heavy loading, the first percentage of your sluice will load up heavy and take some time to exchange out. That means gold will keep traveling until it finds an “empty seat.” If you load too heavy or have too short of a sluice, you’ll have gold flowing over holding zones that are busy working and exchanging. It may take an exchange center (vortex) 3 or 5 seconds to fully process down material and exchange out non-gold and heavies. Fine Tuning: Because of the principles of Hydraulic Equivalence and Incremental Processing, you may have realized that slowing down a sluice can really cause problems and loss of gold. How do you know if your sluice is running too fast or too slow? Experiment! Of course doing so is a little scary because the #1 fear of most gold miners is losing gold, and quite honestly, until your sluice is fine tuned, that just might happen. To avoid losing gold, most miners start running their sluice at the “normal” or widely accepted pitch of 1 inch per foot. But this is just a starting point. If you see gold in your tailings, your first thought is probably to slow it down so you aren’t blowing gold out of the sluice. But perhaps that’s not the cause at all. Perhaps it’s because gold doesn’t have a place to sink down into and hide in your sluice. Experiment by running way too fast, say at a 15-degree pitch. Then take it to 13 degrees, then go down to 12.5. Keep adjusting until you find an acceptable capture rate for the size of gold you want to hold. Lose your fear of losing gold through testing and experimentation. Not only will you fine tune your sluice, but you’ll also get a great education. Good luck! |

|

Nugget of News Blog |

sands. The real reason the Gold Cube was invented was their nemesis— fine

sands. The real reason the Gold Cube was invented was their nemesis— fine  gold. Like any great invention, the Gold Cube was born out of necessity, to solve a real problem, but the process held plenty of struggle and strife. While perfecting the prototypes, the funniest thing Red said to Mike was "Don't believe everything you think!" Their good-natured bickering was actually very productive and the first Gold Cube rolled off the production line in November 2010 (made in the USA, of course) and the first unit was sold in December. Sales have been steady and strong ever since! And just like any gold miner would stake a claim after striking gold, Pung and Wilcox have been issued two patents— both a design and utility patent.

gold. Like any great invention, the Gold Cube was born out of necessity, to solve a real problem, but the process held plenty of struggle and strife. While perfecting the prototypes, the funniest thing Red said to Mike was "Don't believe everything you think!" Their good-natured bickering was actually very productive and the first Gold Cube rolled off the production line in November 2010 (made in the USA, of course) and the first unit was sold in December. Sales have been steady and strong ever since! And just like any gold miner would stake a claim after striking gold, Pung and Wilcox have been issued two patents— both a design and utility patent. Deciding whether to go with a three-stack or four-stack depends on the type of gold itself. The flatter something is, the more it acts like a kite. Kiting is when the gold is so flat that it catches water, flips, and then sails over the waves. The flatter the gold, the more you'll require a

Deciding whether to go with a three-stack or four-stack depends on the type of gold itself. The flatter something is, the more it acts like a kite. Kiting is when the gold is so flat that it catches water, flips, and then sails over the waves. The flatter the gold, the more you'll require a  The fine gold becomes heavier and is moved to the outside edge because of centrifugal force. The gold drops to the bottom and starts scooting up that wall. And, as it leaves the G-force separator, it hits a lip just before it gets to the vortex mat. That edge is the only eddy in the entire system— a low-pressure zone necessary to pull the gold in front of the mat. With a sluicebox, you try hard to get the gold underwater, but with a Gold Cube, the gold doesn't have a choice; it goes under water, under that gate and the low pressure eddy exiting the G-force separator sucks the gold right up in front of the mat. The gold has nowhere to go except into the matting.

The fine gold becomes heavier and is moved to the outside edge because of centrifugal force. The gold drops to the bottom and starts scooting up that wall. And, as it leaves the G-force separator, it hits a lip just before it gets to the vortex mat. That edge is the only eddy in the entire system— a low-pressure zone necessary to pull the gold in front of the mat. With a sluicebox, you try hard to get the gold underwater, but with a Gold Cube, the gold doesn't have a choice; it goes under water, under that gate and the low pressure eddy exiting the G-force separator sucks the gold right up in front of the mat. The gold has nowhere to go except into the matting.