Monday, April 27 2015

What is the best metal detector? This is probably the Number One question that everyone asks when How much do you know about metal detectors? Be honest because the answer also affects your budget. If you're just getting started and plan to go out just a few weekends a year, you may not want to shell out a lot of cash up front so a general all-purpose detector in the $200 range will suit your needs. If you have used a friend's detector a few times and are fairly serious about wanting to find gold and other buried treasures of your own, then buy a detector in the $700 range that is user-friendly. You will get a very good quality machine with plenty of bells and whistles, yet it won't require an advanced degree to actually use it. And you won't have to spend hours reading the owners' manual to understand it either. Before investing in a model that costs thousands of dollars, first be sure you love detecting and will use it often enough to justify the big price tag no matter what brand you decide on. Garrett and Fisher are two of the oldest manufacturers in the business.

What do you primarily hope to find? If you want to find gold, you'll need a detector especially made for that purpose. Gold detectors are not necessarily more expensive, but they are built with a higher sensitivity to detecting gold nuggets, and have better ground balancing and discrimination abilities. PI machines aren't so good for coin shooting in urban areas where you are likely to encounter iron trash, however, they are ideal for beaches or detecting in other highly mineralized soils, especially if you are looking for objects that are deeply buried. VLF detectors are more sensitive to finding the smallest bits of gold, but do not as easily cancel out ground mineralization.

Metal Detectorist Code of Ethics

Saturday, April 11 2015

Thirteen years ago, Park City, Utah was the place Olympic athletes and thousands of spectators visited to “go for the gold” during the 2002 Winter Games. More than 145 years ago, however, an even larger group of people rushed to Park City seeking a different precious metal— silver. The first mining claim was filed in December 1868, and for over a century, the abundant veins found in the Wasatch Mountains surrounding the small town produced about $400 million in silver. When the mining industry slowed down in the 1920s and 30s, Park City's winter sports ramped up. Good money continues to be made today— with snow and tourism. Silver mining, though, is the town’s legacy, and still very much honored around town. Although not well known, Park City’s 300 silver mines were among America’s most productive and longest lasting. Even during the financial panic of 1893 when the bottom fell out of the silver market, Park City weathered the crash because the mines had been doing so well. Thirteen ounces was the average yield of silver per ton of ore from all Park City mines in their 100 years of production. But there was more than silver in them thar' hills. Heavy deposits of lead and zinc also were found around Park City, and in combination with copper and gold, the mining industry generated a total of a half billion dollars in precious metals from the 1870s through 1970s. Park City Museum The best place to learn about the mines, men, machinery, working conditions, town history, and prominent citizens of the day, is at the Mines and Men Park City turned out 23 mining millionaires during its boom years; their photos and biographies are among the museum’s displays. George Hearst, father of newspaper publisher William Randolph Hearst, was one of those fortunate individuals who became tremendously wealthy. Hearst bought the Ontario Mine in 1872 for $27,000 and turned it into a complex underground operation. Sinking six shafts and hundreds of drifts nearly 3,000 feet below the surface required a huge workforce, tons of dynamite, and piles of money, but it was well worth his investment. The Ontario went on to produce more than fifty million dollars, forming the basis for the Hearst fortune. The Ontario was the last silver mine in Park City to close in 1982. In February 1880, the Daly Mining Company was established. The Daly West Mine was one of several owned by John Daly. In 1881, he bought land next to the rich Ontario Mine and sunk a shaft 2,100 feet to reach the ore that extended underground. The Ontario was a silent partner in the enterprise. Within the next year or two, more mines were established. Some of the larger ones included the Crescent, Anchor, and the Mayflower. In 1892, Thomas Kerns, David Keith, Windsor Rice, Albion Emery, and John Judge organized Park City’s most productive mining company by consolidating mines and claims— the largest being the Silver King Mine. For almost 60 years, the company employed the latest technology, following veins to find new and greater ore bodies. The Silver King continued to grow over the years by purchasing neighboring mines and claims. Kearns and Keith were both born in eastern Canada but made their fortunes in Park City. They also became partners in other businesses, including the Salt Lake Tribune, which they purchased in 1901. They died within six months of each other in 1918. Although business at the time was mostly a man’s world, Susanna “Susie” Bransford was known as Utah’s Silver Queen. She married the local postmaster Albion Emery in 1884 , and the couple invested $8,000 in the Mayflower Mine. They really struck it rich when it merged with the Silver King. Susie outlived four husbands, including a Russian prince. By 1894, it was rumored that she was earning $1,000 a day from her interest in the Silver King. With her fortune and flamboyant lifestyle, she was a darling of the nation’s magazines and newspapers for much of her adult life. Most single women back in the day were not so lucky and made their living as “ladies of the night.” Prostitution was a source of income for Park City. Court records show that prostitutes and their “business managers” were regularly arrested, fined, and released. Sadly, suicide by arsenic was a common means to retire from the red light district. Life of a Miner Most early hard rock miners worked for wages, earning $2.75 to $3.50 per day, depending on the job. Many of the miners in Park City in the late 1800s and early 1900s lived in tents. Because times were rough and tough, they usually carried guns and often had cause to use them. Although some men saved enough money to start their own venture such as a butcher store or blacksmith shop, it was mostly the mine owners and investors who got rich. Although a 19th century hard rock miner’s pay wasn’t bad for the time, it meant long hours working in wet, dark, loud, and often dangerous conditions. Very few safety measures were in place. Miners were below ground their entire shift so they brought all their meals with them and ate in the “doghouse” which was a warm, dry room within the tunnels. Some of the early machinery was impressive, but it was basically human and animal muscle that was responsible for the mines’ success. Some beasts of burden spent years underground. Horses were affectionately called “hay burners” by the miners. Horses were treated well because, unlike miners, it was expensive to buy and train another horse. Oilskin slickers and pants were supposed to keep out moisture, but could do only so much. Even mules wore slickers to stay dry in the Ontario drain tunnel. Cats lived underground, too, keeping the mouse population under control. Electricity arrived in Park City in the 1880s but it was a luxury many could not afford. In 1889, it took almost half a day’s mine wages to pay the monthly power bill for a single light. Light bulbs were very expensive and in short supply. To discourage theft, the Silver King Mine stamped their bulbs “Stolen from the Silver King Mine.”Another interesting tidbit you’ll learn at the Park City Museum includes how to clean up with pig fat. A large mercantile at the time, Smith & Brim sold 50 and 100 pound buckets of rendered pig fat (lard). It could be used for cooking or combined with lye to make soap. Thrifty customers made their own soap, often using the same bar to do the laundry, wash the floors, and take a bath! The MEATS sign you’ll see hanging in the museum was the first electrified sign along Main Street. It used 80 light bulbs! Mining Technology

As in most underground mines, water was a constant obstacle. One solution was to use pumps. Another approach was to dig drain tunnels. The Ontario Mine installed a Cornish Pump in 1883. The machine was 30 feet high with a 70-ton flywheel and was imported from Philadelphia by freight wagon. The pump weighed 486 tons and had a capacity of almost four million gallons a day. Later, drain tunnels replaced pumps. The Marsac Mill processed ore from the very first Park City mine— the Flagstaff. The Marsac was a 20-stamp mill. Stamping is a process of crushing ore with huge weights. With 20 stamps operating, the mill could turn out 60-70 tons per day. Because of the long distance the ore had to be hauled to the mill and the technical problems associated with the crude stamp machinery, the Marsac was not necessarily a steady or satisfactory producer, and was only one of such stamping machines that deafened anyone in the vicinity. Before a prospector knew if he had struck it rich, an assayer had to confirm the value of silver in the claim. The Main Street assay office was where miners got the good or bad news. Taking representative core samples, assayers crushed and weighed the ore before pouring it into fireclay crucibles and melting it in the furnace. After cooling, the hardened metal was transferred into a cupel made of bone ash and placed in the furnace once more. The porous cupel absorbed everything but pure silver. The assayer weighed the silver on his delicate scale and calculated silver per ton based on the original ore weight.

Unionization Don’t miss the museum’s “dungeon” where you’ll find old walk-in jail cells along with exhibits on the Miners Union Hall. Mine owners, like all employers in the 19th century, were not held responsible for injuries or deaths. In 1902, an underground explosion at the Daly West Mine killed 34 men. Poison gas spread through tunnels to the Ontario Mine. Accidents like these didn’t happen every day, but they certainly were not rare. Lacking protection, workers organized unions and joined fraternal orders. Both organizations helped their members in difficult times and aided families whose breadwinners were killed or maimed. In 1904, a Miners Hospital was built for $5,000. Funds for the hospital was raised by local businessmen and the Western Federation of Miners Local #144. In the first year, 6,000 miners were treated for silicosis. Tramways When the mines first opened in the Park City area, most ore was hauled in horse-drawn wagons. Eventually more modern devices like the Silver King Tram replaced the wagon teams. Using buckets to haul ore to the mills was an economic success, lowering transportation costs to 22 cents per ton from $1.50 per ton when hauled with teams and wagons. Men could ride to work in the ore buckets from the lower terminal up to the mine. Processed ore was then brought down the mountain and loaded into railroad cars. Another engineering marvel, the Crescent Tramway, was not an overhead tram but a narrow-gauge railroad. In 1885 Shay locomotives (geared steam engines originally developed for the logging industry) pulled ore cars up steep 12 percent grades. Winding down the mountain for five miles from the Crescent Mine, the ore eventually reached the system’s depot and concentrator near Main Street where the ore was refined. Although used until 1900, deep snow covering the tracks rendered the engines useless in winter. Steep grades and heavy downhill loads made for frequent derailments. A winding paved walkway, open to the public, is all that remains of the Crescent Tram. Take a short uphill walk and try to imagine how the narrow gauge trains could possibly traversed the steep terrain. The Greatest Snow on Earth

During this same time, the local mining industry slowed down. The Stock Market crashed in 1929, plummeting the Silver King’s stock from $12.87 to $6.50. Mineral prices continued to drop, and in 1949 most of the mines shut down, putting 1,200 men out of work. Stores closed. People left. The population dropped to 1,150 souls from a peak of 10,000. Within a couple of years, Park City went into ghost town status. In an effort to diversify, United Park City Mines Company opened a ski resort in 1963. The old Spiro Mine drain tunnel was converted into an underground ski lift. This electric mine train, which you will see in the museum, carried skiers three miles into the mountain where a hoist then lifted them 1,800 feet to the surface. Since it took an hour to transport skiers, the Spiro tunnel wasn’t all that popular, but word spread about the great snow, and people started moving to the area. Over the next few decades, world-class ski resorts and high-speed chairlifts were built, annual art and film festivals were established, and in 2002 Park City hosted many of the XIX Winter Games. Park City today is a good example of a boom and bust mining town booming again—revitalized in grand style as a year-round mountain resort and international tourist destination. In 2008, Forbes Traveler magazine named Park City as one of “America’s 20 Prettiest Towns.” More than 60 of Park City's buildings are listed on the National Register of Historic Places, many of which are located along the town's Main Street alongside restaurants and plenty of shops and boutiques. Two years running— 2008 and 2009— Deer Valley Resort was named the number one ski resort in North America by SKI magazine. Whether you like to ski, shop, eat, hike, mountain bike, or just take in the scenery, a visit to Park City is a great place to treasure America’s mining heritage. Park City Museum • 528 Main St. • Park City, Utah 84060 • Phone: (435) 649.7457 Article and text by Denise Seith. First published in the March/April 2015 issue of Gold Prospector's Magazine. Click image on right to download .pdf of this article. Monday, April 06 2015

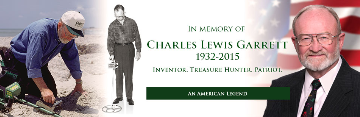

It is with great sadness that we share the news that Dr. Charles L. Garrett died on April 3, 2015. We are grateful for the contributions Dr. Garrett made to our industry, and for the fine example he always put forth for others. The Garrett name will always be synonymous with high-quality metal detectors, including those used in security applications, law enforcement, military, sports, and outdoor recreational use. Although he will be dearly missed by many, his legacy will endure.

Charles L. Garrett —inventor, entrepreneur, treasure hunter, patriot, husband, and father—died on April 3, 2015. A native Texan and resident of Garland, Dr. Garrett and his wife Eleanor in 1964 founded Garrett Electronics which grew to become the world’s largest manufacturer of metal detection equipment. |

|

Nugget of News Blog |